We at Qmax Ion truly understand that no size fits all. Qmax has a team of battery design engineers who constantly work on customised battery solutions which are optimally designed and tailor made according to the core requirements of the customer.

A customised battery pack is a battery system that is specifically designed and built to meet the unique requirements of a particular application.

This could include factors such as voltage, capacity, size, shape, weight, energy density, discharge rate, and other specific performance characteristics.

Key aspects of customised battery packs

Qmax Ion’s custom battery packs are tailored to the specific needs of the application they will be used in. This could include various industries such as automotive, aerospace, marine, medical devices, robotics, energy storage systems, and more. The battery pack is designed to meet the power demands and physical constraints of the intended application.

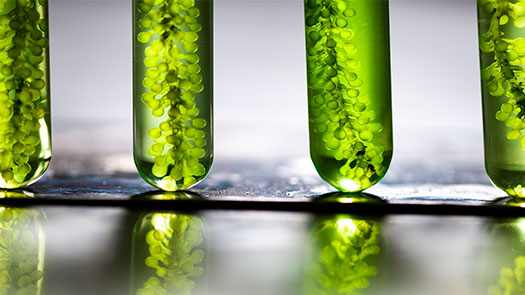

The choice of battery chemistry depends on the specific requirements of the application. Common battery chemistries used in custom battery packs include Nickel Manganese Cobalt (NMC), Lithium Iron Phosphate (LFP), Lithium Manganese Iron Phosphate (LMFP), and Lithium Titanium Oxide (LTO). Each chemistry has its own advantages and limitations in terms of energy density, cycle life, safety, cost, and environmental impact.

The voltage and capacity of a customised battery pack are determined based on the power requirements and runtime of the application. The pack can be designed to operate at a specific voltage, such as 12V, 24V, 48V, or higher, and the capacity is measured in ampere-hours

(Ah) or watt-hours (Wh).

A BMS is an essential component of a customised battery pack. It ensures the safe and efficient operation of the battery by monitoring individual cell voltages, managing charging and discharging, balancing cell capacities, and protecting against overcharging, over-discharging, and thermal issues.

Custom battery packs can be designed to fit specific physical constraints and mounting requirements of the application. The size, shape, and weight of the battery pack can be optimised to ensure proper integration and efficient use of space. Various heat dissipation methods and techniques are also introduced in the mechanical design phase.(Ah) or watt-hours (Wh).

Custom battery packs should adhere to safety standards and regulations relevant to the application and industry. Compliance with safety certifications, such as BIS (Bureau of Indian Standards), UL (Underwriters Laboratories) or IEC (International Electrotechnical Commission), may be required depending on the intended use of the battery pack.

AIS 156. The AIS 156 norms are specifically for electric two-wheelers, three-wheelers, and quadricycles. The certification is focused on the electric powertrain and the Rechargeable Electrical Energy Storage System (REESS) of the vehicles.

Developing a customised battery pack often involves collaboration between us and the customer to ensure that the pack meets all the necessary specifications and requirements. Working with an experienced battery manufacturer like Qmax Ion can help ensure the successful development and implementation of a customised battery pack for your specific application

A customised battery pack is a battery system that is specifically designed and built to meet the unique requirements of a particular application. This could include factors such as voltage, capacity, size, shape, weight, energy density, discharge rate, and other specific performance characteristics.